RESEARCH FEATURE: Fruits are increasingly being transported from the field to the market in thermoformed clamshell packages. And, with the help of a new federal grant and laser technology, a team led by R. Paul Singh hopes to build a better box, or package, in this case — so that when produce arrives in stores, it is as fresh as possible.

The berry industry began packing its product in thermoformed plastic packages about 10 years ago. During the last few years, these clamshell packages have been increasingly used for table grapes, cherries and pears, says Singh.

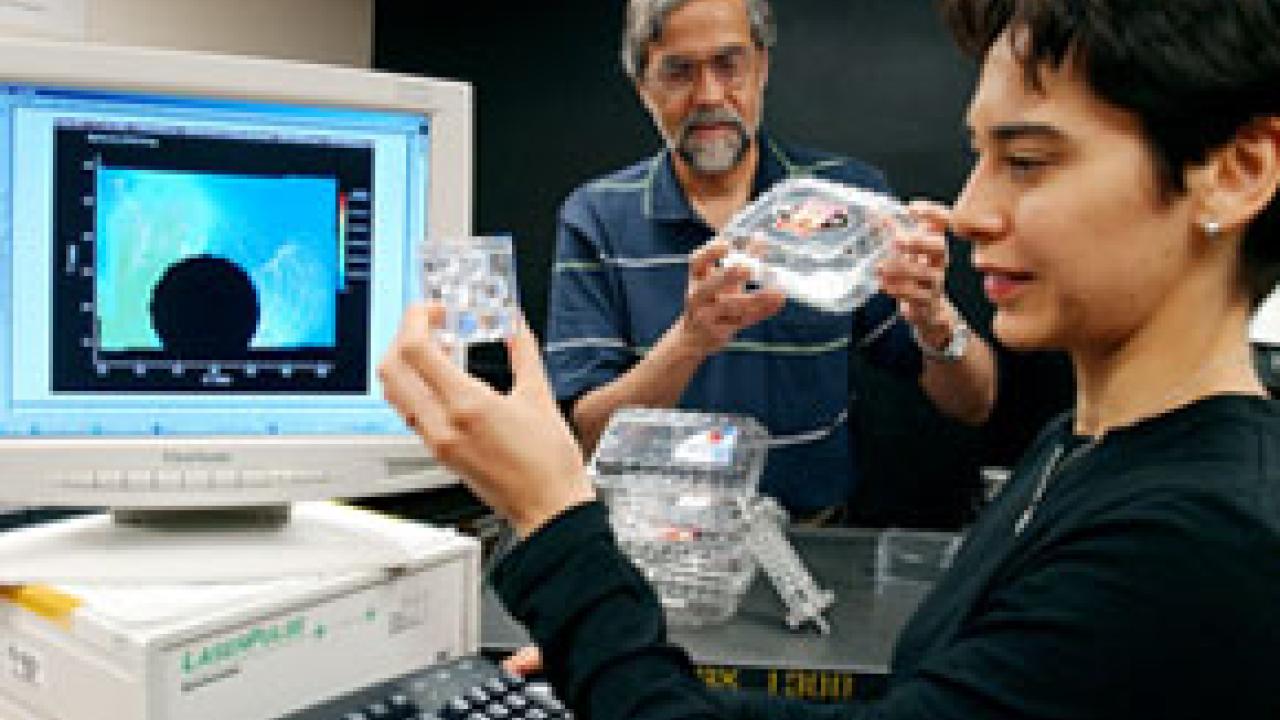

The professor of food engineering is principal investigator for the $300,000 U.S. Department of Agriculture grant to study new packaging design options for produce.

The consumer will benefit from the availability of fresher produce at a more cost-effective price. Meanwhile, buyers of packaging systems will no longer need to depend on expensive empirical testing of a multitude of designs to determine which commercially available packaging system cools most effectively, notes Singh.

Controlling the uniformity of cooling and cooling rate of freshly harvested fruit is key to maintaining its freshness. But managing those rates is tricky. Experiments show they are affected by a complex interaction of package-design parameters, such as percentage of total vent area, vent spacing and vent size, not to mention the arrangement of containers on pallets.

Low and non-uniform airflow through the product results in slow and non-uniform cooling, says Singh. This is particularly a problem on hot days when a crop must be harvested in large quantities, he says, noting that measurable quality loss occurs in just a few hours of cooling delay.

"Our goal is to use computational fluid dynamics and a laser-based measurement system to understand how air flows inside a package and investigate new packaging designs for uniform cooling of the product."

----------

For more articles about researchers' work spotlighted in the recent issue of Dateline, including the work of Alex Ardans and California Pilot Project members, click here.Media Resources

Amy Agronis, Dateline, (530) 752-1932, abagronis@ucdavis.edu